Injection Molded Pallets

Introduction

Injection Molded Pallets have become the go-to choice for businesses looking for durable, lightweight, and cost-effective pallet solutions. Designed using high-pressure injection molding technology, these pallets provide superior load-bearing capacity, hygiene, and long-lasting performance. Whether for warehouses, logistics, or heavy-duty industrial applications, Injection Molded Pallets offer unmatched strength and reliability.

What Are Injection Molded Pallets?

Injection Molded Pallets are plastic pallets manufactured through a high-pressure molding process that ensures precision, consistency, and durability. These pallets come in various configurations, including perforated, reversible, and flat-top designs, catering to different industry needs.

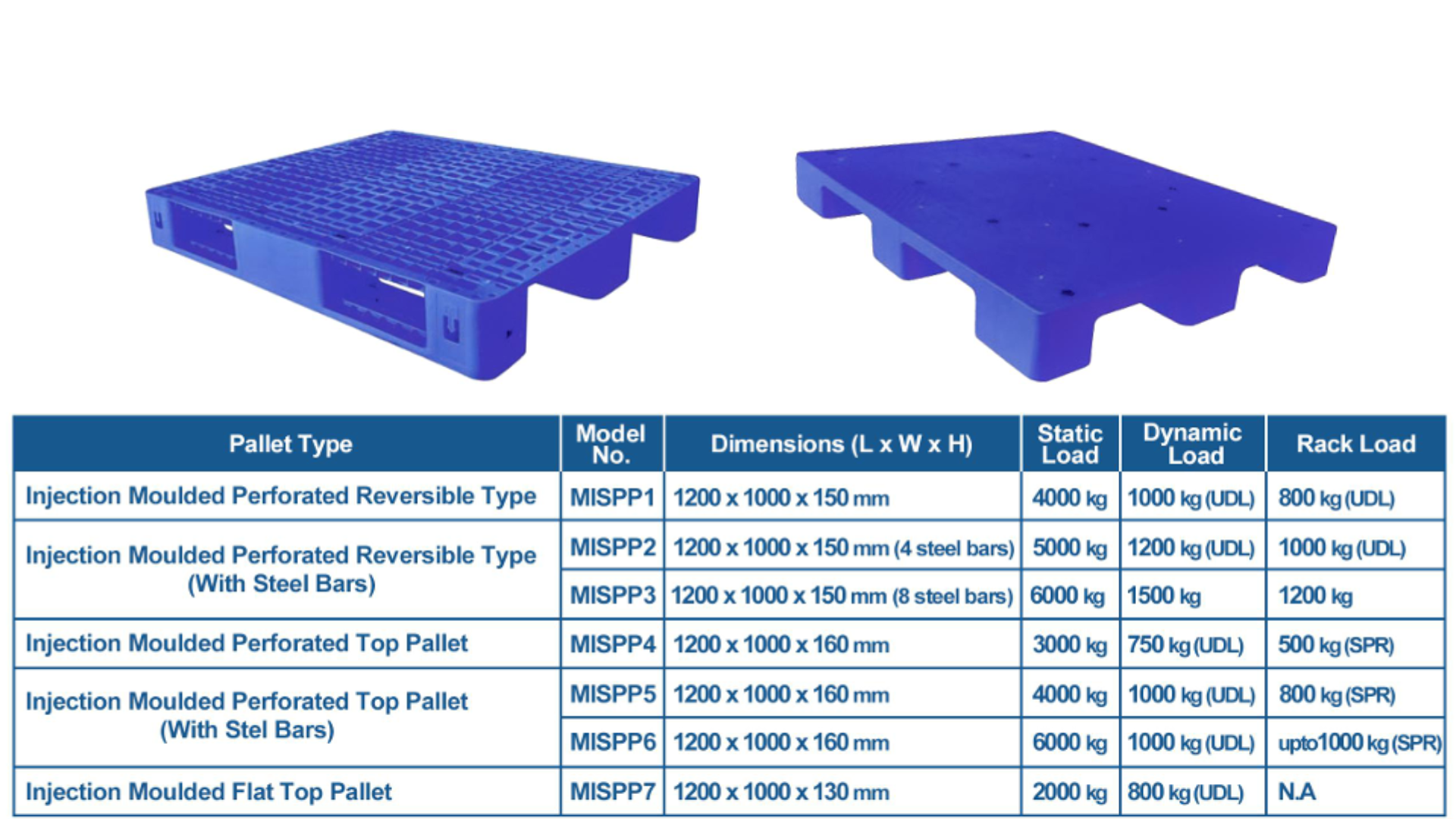

Types of Injection Molded Pallets & Their Specifications

Below is a detailed breakdown of different Injection Molded Pallets and their respective load capacities.

| Pallet Type | Model No. | Dimensions (L × W × H) | Static Load | Dynamic Load | Rack Load |

|---|---|---|---|---|---|

| Injection Molded Perforated Reversible Type | MISPP1 | 1200 × 1000 × 150 mm | 4000 kg | 1000 kg (UDL) | 800 kg (UDL) |

| Injection Molded Perforated Reversible Type (With Steel Bars) | MISPP2 | 1200 × 1000 × 150 mm (4 steel bars) | 5000 kg | 1200 kg (UDL) | 1000 kg (UDL) |

| MISPP3 | 1200 × 1000 × 150 mm (8 steel bars) | 6000 kg | 1500 kg | 1200 kg | |

| Injection Molded Perforated Top Pallet | MISPP4 | 1200 × 1000 × 160 mm | 3000 kg | 750 kg (UDL) | 500 kg (SPR) |

| Injection Molded Perforated Top Pallet (With Steel Bars) | MISPP5 | 1200 × 1000 × 160 mm | 4000 kg | 1000 kg (UDL) | 800 kg (SPR) |

| MISPP6 | 1200 × 1000 × 160 mm | 6000 kg | 1000 kg (UDL) | Up to 1000 kg (SPR) | |

| Injection Molded Flat Top Pallet | MISPP7 | 1200 × 1000 × 130 mm | 2000 kg | 800 kg (UDL) | N.A |

Key Features of Injection Molded Pallets

- High Load Capacity – Supports static loads up to 6000 kg and dynamic loads up to 1500 kg, making them suitable for heavy-duty industrial use.

- Durable & Long-Lasting – Made from high-quality plastic, ensuring a longer lifespan compared to wooden or traditional pallets.

- Hygienic & Easy to Clean – Resistant to moisture, bacteria, and chemicals, making them perfect for food, pharmaceuticals, and clean environments.

- Lightweight & Cost-Effective – Reduces shipping costs while maintaining high durability and strength.

- Rack Compatibility – Options available with rack loads up to 1200 kg, ideal for warehouse stacking and optimized space utilization.

- Customization with Steel Bars – Pallets with 4 or 8 steel bars provide extra strength and stability, perfect for heavy and high-rack storage.

Benefits of Using Injection Molded Pallets

✅ Eco-Friendly – 100% recyclable and sustainable.

✅ Weather & Corrosion Resistant – Performs well in hot, cold, and humid environments.

✅ Forklift & MHE Compatible – Designed for seamless handling with forklifts, conveyors, and automated storage systems.

✅ Safer Alternative to Wooden Pallets – No nails, splinters, or risk of contamination.

✅ Versatile Applications – Used in warehousing, logistics, pharmaceuticals, food storage, retail, and manufacturing industries.

Conclusion

Injection Molded Pallets are an essential investment for businesses looking for reliable, durable, and hygienic pallet solutions. With various configurations and load capacities, they provide a versatile and cost-effective alternative to traditional wooden pallets. Whether for heavy-duty applications or hygienic environments, these pallets ensure efficiency, safety, and long-term savings.

👉 Looking for high-performance Injection Molded Pallets for your operations? Contact us today to explore our range of models!